ISO 9001 is considered the world’s most recognized quality management standard. ISO 9001:2015 (a subset of ISO 9001) offers a structured framework for building and maintaining a Quality Management System (QMS). From timelines to auditor roles to buyers’ intent, this benchmark evaluates various parameters before awarding any product or service its certificate.

The scope of the standard is inherently broad, as it covers all manufacturing or processing in detail. However, here’s a guide that covers everything you need to know about ISO 9001 certification.

| TL;DR ISO 9001 is the global standard for building and maintaining a robust Quality Management System (QMS). Certification involves aligning your processes with ISO 9001 standards, conducting a gap analysis, training teams, implementing required controls, and undergoing an external audit by an accredited body. Once certified, you maintain it through annual surveillance audits and periodic recertification. ISO 9001 certification signifies operational discipline and global credibility, enabling businesses to win trust, reduce inefficiencies, and meet the expectations of both customers and regulators. |

Automate ISO 9001 from gap analysis to certification.

👉 Book a demo →

What is ISO 9001 certification?

The ISO 9001 is an international standard for a Quality Management System (QMS). Published by the International Organization for Standardization (ISO), it provides a framework for companies to deliver reliable outcomes, meet regulatory requirements, and enhance customer confidence through structured systems and continuous improvement.

Who needs ISO 9001 certification?

The scope of ISO 9001 certification is not limited to any specific industry or business of any size. Its versatile quality management practices are standardized to meet global adoption. Here’s how different industries leverage the ISO 9001 certification to their benefit:

- Manufacturing: From electronics to automotives, manufacturers rely heavily on ISO 9001 to minimize defects and ensure consistent product quality by implementing standardized workflows, rigorous quality checks, and continuous process improvements.

- Information Technology and SaaS: ISO 9001 aids tech and SaaS companies in streamlining software development cycles, enhancing customer support through defined protocols, and ensuring high service uptime with robust quality management practices.

- Logistics and Supply Chain: Logistics companies, on the other hand, adopt ISO 9001 too to optimize delivery timelines, reduce errors in order fulfillment, and strengthen vendor relationships through clear quality standards and performance monitoring.

- Construction and engineering: The construction and engineering industries benefit from the ISO 9001 standard through project planning, risk management, and contractor oversight in construction and engineering by enforcing structured processes, quality audits, and proactive issue resolution.

Why get ISO 9001 certified?

The ISO 9001 certification helps businesses identify inefficiencies and streamline processes, leading to a reduction in waste and improvements in the overall productivity of the setup. Key benefits include:

- Operational Efficiency: Identifies inefficiencies, streamlines processes, and reduces waste, boosting overall productivity.

- Global Recognition: Aligns processes with international standards, enhancing credibility and access to quality-driven markets.

- Increased Revenues: Improves product/service quality, leading to higher customer satisfaction and financial gains.

- Enhanced Employee Morale: Fosters a culture of quality and accountability, improving workforce engagement.

- Improved Risk Management: Strengthens proactive identification and mitigation of operational risks.

Core principles of ISO 9001

The core principles of ISO 9001 are built around creating a high-functioning, improvement-driven organization. 7 quality management principles form the foundation of ISO 9001:

1. Customer Focus

The primary goal of any quality management system is to meet customer requirements and strive to exceed expectations.

- When every part of the organization aligns around delivering customer value, it builds trust, loyalty, and long-term business success.

- This principle encourages you to understand customer needs deeply and act on feedback to enhance satisfaction continually.

2. Leadership

Strong leadership fosters a sense of purpose, alignment, and a shared direction across the organization.

- Leaders set the tone for quality by defining a clear vision, establishing measurable goals, and modeling the behaviors needed to achieve them.

- An engaged leadership team fosters a culture where quality is a shared responsibility, rather than a siloed initiative.

3. Engagement of People

Organizations perform at their best when people at all levels are empowered, competent, and actively engaged in achieving their objectives.

- When individuals understand their role in the quality system and are encouraged to contribute ideas, overall performance improves.

- Recognition, training, and open communication are essential to unlocking employee potential and building a high-trust, high-impact culture.

4. Process Approach

Viewing activities as interconnected processes enables more consistent and predictable results.

- Managing workflows as structured processes with defined inputs, activities, and outputs helps reduce inefficiency, rework, and errors.

- This approachenables easier monitoring, optimization, and scaling ofoperations without compromising control or quality.

5. Improvement

A commitment to continual improvement is essential for staying competitive and adaptable.

- Organizations that embed improvement into daily operations are better equipped to respond to changing needs and emerging risks.

- This principle supports a growth mindset, where even minor adjustments compound into meaningful performance gains over time.

6. Evidence-Based Decision Making

Effective decisions are based on accurate data, not assumptions or intuition.

- Using measurable facts ensures that corrective actions and strategy shifts are grounded in reality, not guesswork.

- This principle reduces risk, boosts confidence, and enables more intelligent resource allocation.

7. Relationship Management

Sustained success depends on how well an organization manages its relationships with suppliers, partners, and other stakeholders.

- Collaborative and transparent relationships across the supply chain enhance quality, responsiveness, and innovation.

- By aligning goals and expectations, you reduce friction and increase resilience in complex operational environments.

ISO 9001 Certification process

The ISO 9001 certification process involves preparing your quality management system to meet ISO 9001 standards, followed by an external audit by a certified body. If the requirements are met, the organization is awarded ISO 9001 certification, which is valid for three years and requires annual surveillance audits.

Here’s a more detailed look at the eight critical stages of the ISO 9001 certification lifecycle:

1. Gap Analysis (Baseline Diagnostic)

The journey begins with a structured diagnostic review, benchmarking your current quality systems against ISO 9001:2015 clause by clause. This covers process controls, leadership, documentation, risk-based thinking, and customer focus. The outcome is a clear remediation map outlining gaps and next steps.

Conduct a gap analysis with an ISO 9001 clause-by-clause checklist

2. Training & Awareness (Organization-wide Enablement)

Next, key stakeholders, from leadership to frontline staff, are trained on the basics of ISO 9001, including the process approach, PDCA cycle, and risk-based thinking. Targeted sessions and role-specific training help process owners, auditors, and quality teams align and prepare for the cultural shift.

3. Documentation Development (QMS Blueprinting)

Once your teams are primed, you move into the documentation phase. This includes drafting or updating:

- Quality Manual (if applicable)

- Quality Policy and Objectives

- Documented procedures (as required)

- Process maps and flowcharts

- Control of documented information

- Records for traceability and audit readiness

4. Implementation (System Activation)

Implementation involves embedding new policies and procedures into daily work, configuring supporting systems like document control and nonconformity tracking, and ensuring consistent execution. Leadership must reinforce a culture of compliance and establish ongoing feedback mechanisms.

5. Internal Audit (Pre-Certification Readiness Check)

Trained internal auditors now conduct formal audits across all departments and processes to validate implementation. The objective is to:

- Identify nonconformities or process lapses

- Test compliance against ISO 9001 clauses

- Gather objective evidence (records, reports, logs)

- Prepare for the external audit

Findings are logged, and corrective actions are initiated and tracked to closure before inviting the external certifier.

6. Management Review (Strategic Alignment Checkpoint)

The executive team reviews the entire QMS to:

- Assess performance metrics (KPIs)

- Review audit findings, customer feedback, and process issues

- Make decisions on resourcing, improvements, and objectives

This review isn’t symbolic—it’s a mandatory checkpoint where leadership validates whether the QMS supports business strategy and ISO 9001 compliance.

7. Certification Audit (Stage 1 + Stage 2 by External Body)

An accredited Certification Body (CB) conducts a two-stage audit:

- Stage 1: Documentation review, scope validation, and readiness check

- Stage 2: Full-scale audit across all operational processes, departments, and functions

The CB evaluates evidence, interviews stakeholders, and assesses conformity to all ISO 9001:2015 clauses. Findings are categorized as minor or major nonconformities or observations.

8. Certification (ISO 9001 Credential Issuance)

Once nonconformities are resolved and verified, the Certification Body issues the ISO 9001 certificate, which is valid for three years and requires annual surveillance audits. The certificate reflects operational excellence, risk-aware management, and global credibility in quality assurance.

Pro tip: ISO 9001 can be integrated with frameworks like SOC 2 or ISO 27001 to boost efficiency and reduce audit fatigue. A platform like Sprinto helps automate evidence collection, streamline audits, and maintain continuous QMS compliance.

Cost of ISO 9001 certification

The ISO 9001 certification does not come at a fixed cost. The total cost is a combination of several internal and external deciding factors, and you can expect a price tag of anywhere from $5000 to more than $40000.

| Company size | Cost range | What it includes |

| Small (1-25 employees) | $5,000 – $10,000 | Gap analysis, basic training, documentation support, and audit fees |

| Mid-size (26-100 employees) | $10000-$20000 | Process mapping, staff training, internal audits, and external certification audit |

| Large (100+ employees) | $20000-$40000+ | Multi-department rollout, advanced QMS integration, complete audit prep, and support |

If you want a more nuanced and detailed cost breakdown, consider using the cost calculator by Sprinto.

The cost of ISO 9001 certification depends on the organization’s size, industry complexity, certification scope, gaps in existing processes, and whether internal or external support (e.g., consultants or tools like Sprinto) is utilized.

Larger, more complex organizations in regulated industries with significant gaps often face higher costs due to the extensive audits, documentation, and preparation efforts required.

How long does ISO 9001 certification take?

Achieving ISO 9001 certification depends upon a host of factors that span across an organization’s strengths, resources, and readiness. The process usually takes three to six months and includes time for preparation, mock internal audits, iterations or implementations based on results as per the mock audits, and lastly, the certification audit.

How long is the ISO 9001 Certification valid?

ISO 9001 certification is valid for a period of three years. To maintain this certification, your organization must undergo annual surveillance audits conducted by the Certification Body. These audits verify that your quality management system (QMS) remains compliant and is being followed in daily operations.

At the end of the three-year cycle, a recertification audit is required to renew the certification. This full audit reassesses the QMS to ensure continuous improvement and alignment with ISO 9001 standards. Failing to complete surveillance or recertification audits on time can result in suspension or withdrawal of the certificate.

ISO 9001 auditor and lead auditor certifications

The ISO 9001 certification doesn’t apply to organizations alone. Professionals often seek to earn auditor credentials to evaluate Quality Management Systems (QMS) based on ISO 9001 standards. These certifications are crucial to conducting internal or third-party audits and are sought after as they open up careers in regulatory compliance, quality assurance, and certification bodies.

Roles and Responsibilities

The responsibilities of an internal ISO 9001 auditor and lead auditor are well defined. Simply put, while the internal auditors are essential for maintaining ISO certification, lead auditors complete advanced training and demonstrate audit leadership skills. This is often achieved through a combination of coursework and real-life audit experience. Here are the roles and responsibilities of each of them:

1. Internal Auditor

- Evaluate the effectiveness of the internal QMS

- Ensure ongoing compliance with ISO 9001 requirements

- Identify gaps, opportunities, and non-conformities for improvements

- Help prepare for external audits

2. Lead Auditor

- Lead audit teams during large-scale or multi-site certification audits

- Ensure compliance with audit standards and ethical practices

- Plan, schedule, and manage the entire process

Eligibility Criteria

| Criteria | Internal auditor | Lead auditor |

| Prior QMS Experience | Helpful but not required | Typically required |

| ISO 9001 knowledge | Required | Required in-depth |

| Formal training | 2-3 day course | IRCA/Exemplar Global 5-day course |

| Audit experience | Optional | Minimum 20+ audit days |

| Industry expertise | Nice to have | Often required by a certification body |

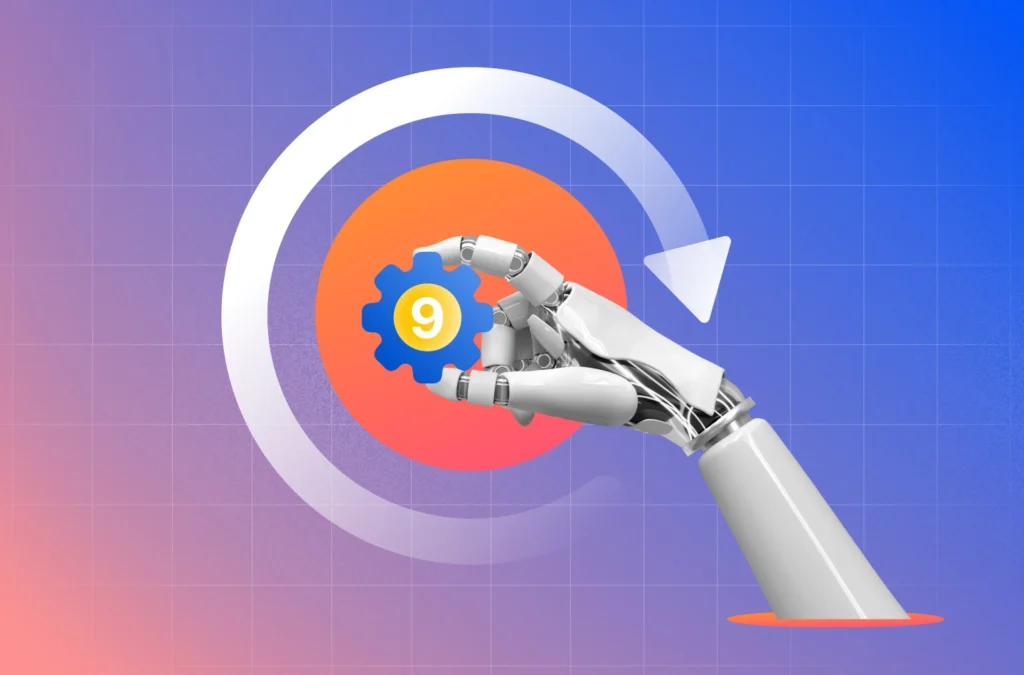

How does Sprinto help automate ISO 9001 compliance?

ISO 9001 no longer needs to be a slow, manual, document-heavy exercise. With Sprinto and Sprinto AI, organizations move from reactive, spreadsheet-driven quality management to continuous, automated, and audit-ready compliance.

By auto-mapping controls, streamlining evidence collection, identifying gaps in real time, and providing hyper-contextual guidance throughout your QMS, Sprinto reduces months of manual work to a fraction of the time. The result: fewer errors, faster audits, and a quality program that stays aligned as your systems evolve.

Sprinto AI doesn’t just help you get ISO 9001 certified; it helps you stay compliant effortlessly. Take a platform tour to kickstart your journey.

The ISO 9001:2026 Update: What’s changing?

ISO 9001:2026 is an evolutionary update rather than a complete rewrite, maintaining the same high-level structure and core clauses (4–10). However, several targeted improvements have been introduced to reflect modern operational and societal needs:

- Leadership Accountability: Clause 5.1.1 now explicitly requires leaders to promote a culture of quality and uphold ethical behavior, expanding the role of top management beyond operational oversight.

- Risk & Opportunity Management: Clause 6.1 has been restructured into clearer sub-clauses (6.1.1 to 6.1.3), with enhanced guidance in Annex A to help organizations more effectively identify and manage risks.

- Climate Considerations: Clause 4.1 (context of the organization) now includes environmental and climate factors, encouraging companies to consider broader systemic risks.

- Terminology & Clarity: Several terms and notes have been refined for improved interpretation, particularly in relation to decision-making, documentation, and stakeholder expectations.

Timeline: ISO 9001:2026 is expected to be published in September 2026, with a three-year transition period ending in September 2029.

Next Steps: Organizations should continue with the implementation of ISO 9001:2015, as it’s highly compatible with the 2026 revision. Begin reviewing leadership engagement, risk management practices, and climate-related considerations to align early. Preparing now ensures a smooth transition and positions your business as a forward-thinking operator.

FAQs

The journey to getting ISO 9001 certified begins with understanding the ISO 9001 requirements and then conducting a gap analysis. Next, develop and implement a QMS that aligns with the standard. After successful internal and external audits, the certification is awarded by the auditor.

On average, the cost of ISO 9001 certification ranges between $3,000 and $7,000. This includes the costs of consultancy, training, and certification body fees.

The ISO auditor training equips individuals with the necessary skills to assess and audit QMS against ISO 9001 standards.

To verify the validity of an ISO certificate, you can use the IAF CertSearch, an online register maintained by the International Accreditation Forum (IAF).

There’s no single “best ISO” certification, as it depends upon the specific needs and goals of an organization. However, ISO 9001 is the most recognized and used standard for QMS.

It is not an either/or choice between ISO 9001 and Six Sigma; both can be used in conjunction. ISO 9001 provides the QMS framework, while Six Sigma helps business owners implement and maintain a quality management system.

ISO 9001 certification is valid for three years, with annual surveillance audits required to maintain it. After three years, a full recertification audit is needed to renew the certificate and confirm ongoing compliance.

The seven core principles of ISO 9001 are:

– Customer Focus: Meet and exceed customer expectations to drive satisfaction and loyalty.

– Leadership: Establish a clear vision, align the organization, and foster a quality-driven culture.

– Engagement of People: Empower employees at all levels to contribute to quality and improvement.

– Process Approach: Manage activities as interconnected processes for consistent, efficient results.

– Improvement: Commit to continual improvement to stay competitive and agile.

– Evidence-Based Decision Making: Use data and facts to guide decisions and actions.

– Relationship Management: Build strong, mutually beneficial relationships with suppliers and stakeholders.

ISO 9001:2026 introduces minor updates to strengthen leadership accountability, expand risk management guidance, and incorporate climate-related considerations into business planning. The overall structure and core requirements remain unchanged, so current ISO 9001:2015 users face minimal disruption.

Pansy

Pansy is an ISC2 Certified in Cybersecurity content marketer with a background in Computer Science engineering. Lately, she has been exploring the world of marketing through the lens of GRC (Governance, risk & compliance) with Sprinto. When she’s not working, she’s either deeply engrossed in political fiction or honing her culinary skills. You may also find her sunbathing on a beach or hiking through a dense forest.

Explore more

research & insights curated to help you earn a seat at the table.